Blown Away: Honda’s New Wind Tunnel Raises Research Bar

MAR 29, 2022

In the race to develop the most efficient vehicles, Honda took a big step this week when it opened its $124 million, state-of-the-art wind tunnel facility in central Ohio.

The new Honda Automotive Laboratories of Ohio (HALO) is located a few miles northwest of Marysville, Ohio, where Honda has one of its largest U.S. automotive plants and the massive independent Transportation Research Center resides. The HALO wind tunnel will primarily be used for developing passenger cars, but it figures to pay major motorsports dividends as Honda now has its own facility where staff members work full time in a single location.

Currently, Honda Performance Development, the U.S. motorsports subsidiary participating in the NTT INDYCAR SERIES, does much of its wind tunnel work at Windshear, located on the north edge of the Concord-Padgett (North Carolina) Regional Airport. Future development moves to the HALO wind tunnel.

Five race teams and 15 drivers are competing full time with Honda in the NTT INDYCAR SERIES this season. Honda won last year’s Indianapolis 500 presented by Gainbridge with Helio Castroneves driving the No. 06 AutoNation/SiriusXM Honda of Meyer Shank Racing. Alex Palou won the season championship driving the No. 10 NTT DATA Honda of Chip Ganassi Racing.

Honda considers the HALO wind tunnel to be the world’s most advanced wind tunnel, with multifunctional capabilities – aerodynamics, aeroacoustics and motorsports -- in one location.

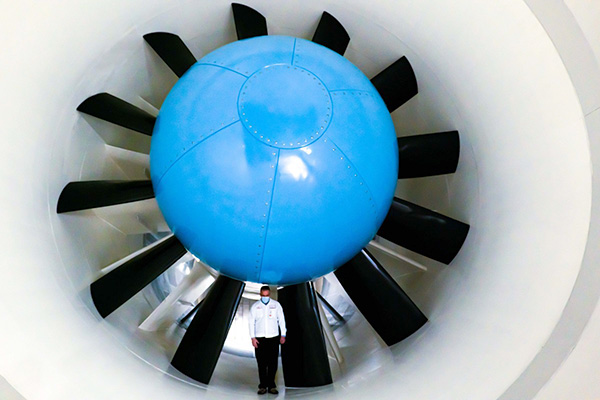

Powered by a 26-foot fan operating at 6,700 horsepower, the HALO wind tunnel can send gusts through the 1/8-mile wind tunnel at nearly 193 mph, among the world’s fastest tunnels.

Powered by a 26-foot fan operating at 6,700 horsepower, the HALO wind tunnel can send gusts through the 1/8-mile wind tunnel at nearly 193 mph, among the world’s fastest tunnels.

“That’s really critical to represent the flow conditions going down the front straight at Indianapolis (Motor Speedway),” said Drew Wetzel, a senior aerodynamics engineer at HPD.

A single, wide-belt rolling road can test downforce work ideal for race cars. While it is standard for a tunnel to be able to measure the downforce beneath each wheel, Wetzel said the HALO wind tunnel can measure drag using a balance under the rolling road system, eliminating interference from rolling resistance.

Other HALO wind tunnel features include a remote control system to characterize the aerodynamic performance at varying ride height conditions. Also, a traverse allows for off-body flow measurements of pressure and velocity in the wake of the vehicle or the conditions around it.

The HALO wind tunnel can adjust the testing conditions from 50 degrees to 122 degrees, maintaining constant temperature. Its turntable allows for 180-degree rotation of the vehicle.

The ability to test acoustics is a key aspect of Honda’s move to electrification. The HALO wind tunnel can be converted to acoustic mode in less than an hour, complete with a powerful system of acoustic arrays made up of microphones and cameras, collecting real-time data and precision measurement. The system is said to be so quiet that at wind speed of 87 mph, the noise level outside the airflow is less than a normal conversation.

What cannot be understated is the impact the HALO wind tunnel will have on the recruitment and development of the engineers working at the facility. Roughly two-thirds of the 20-person HALO wind tunnel staff have been hired within the past year in the buildup to the facility’s opening earlier this week. That means new blood for the motorsports side of Honda’s business.

“We’re going to have production development engineers working side by side with HPD engineers along with the engineers that run the facility, so all of those people will have different experiences and different processes and different techniques,” said Mike Unger, who leads the HALO wind tunnel program. “Through all of that collaboration, we will be able to develop new procedures and new techniques that will benefit everybody.

“This is a huge point for us. We think it’s actually going to be the biggest strength of this facility in the future.”

The HALO wind tunnel is configured with four secure bays allowing for third-party customers, which would include INDYCAR staff. Unger anticipates customers being able to use the facility beginning in 2023.